Example of use of MM-2 Ultra-Refiner & MM-2 Super-Finisher

Case 01: Back-straining and de-foaming (or decreasing foam) of functional food material

Back-straining the functional food material removes particles and fibers which are in the material and the main causes of rough texture and harshness on the throat, thus, getting the material smooth and easy to eat and swallow.

Simultaneously, de-foaming (or decreasing foam) helps prevent oxidation

and improve fluidity of the material at time of its filling work.

The material before back-straining

Contains coarse particles and fibers which are main causes of roughness

Also, is of high viscosity and foam involvement

The material after back-straining

The material becomes smooth and its de-foamed (or foam decreased) condition is seen

Case 02: Almond(or apricot kernel) extraction

The white kernel of almond seed is soaked in water and crushed by grinding with water for making a feeding material into our machine.

Then, the material is pressed by our machine to separate liquid and solid

portions.

This process is similar to the case of making soy milk.

Raw material of almond and water

Feeding material after watering and crushing

Feeding material is put directly into the hopper at the upper part of the

machine and pressed.

The solid portion, after press-process is discharged from the valve at the machine end.

MM-2 Ultra-Refiner, self-feeding type with hopper is used.

The solid portion, after press-process is discharged from the valve at the machine end.

MM-2 Ultra-Refiner, self-feeding type with hopper is used.

Good flavor of almond

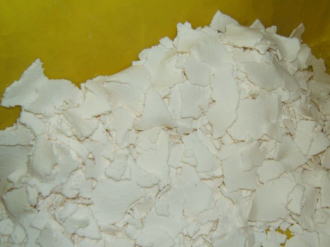

Pressed solid portion